Table of Contents

What is Projected Capacitive Touchscreen

Projective capacitive touch (PCAP) is a type of touch-sensitive display technology that utilizes the principle of capacitance to detect the presence and location of a human finger or other conductive object. This technology is widely used in smartphones, tablets, industrial panels, and automotive displays due to its accuracy, durability, and multi-touch capabilities, PCAP has become the dominant touch technology in the market.

Brief History of Capacitive Touch Technology

The history of capacitive touch technology is a fascinating journey that spans decades, marked by innovative breakthroughs in electronics and human-computer interaction. Here’s an overview of its evolution:

Early Beginnings

1965: E.A. Johnson at the Royal Radar Establishment in the UK developed one of the earliest touchscreen concepts. His work described a capacitive touch interface for controlling air traffic displays, though it was quite basic.

1970s: Capacitive touchscreens were refined further. These early systems used a single-layer capacitive sensor, detecting touch by changes in electrical capacitance when a conductor (like a human finger) came close.

Commercialization and Refinement

1983: Hewlett-Packard introduced the HP-150, one of the first touchscreen computers. It used infrared technology, but capacitive systems were gaining attention for their durability and precise input detection.

Capacitive touchscreens started appearing in industrial and specialized applications, such as control panels and medical equipment. Technologies were still expensive and not widely adopted for consumer products due to cost and complexity.

Early Consumer Adoption

Capacitive touch technology started appearing in kiosks, ATMs, and point-of-sale systems due to its resilience and ability to detect touch even with contaminants on the screen.

Developers began experimenting with multi-touch technology, paving the way for more advanced interaction methods.

Consumer Electronics Revolution

2007: The release of the LG Prada and Apple iPhone were a major turning point. They used a projected capacitive touch screen (PCAP), which allowed multi-touch gestures and high responsiveness. This revolutionized how users interacted with devices.

Competitors like Samsung, HTC, and others soon adopted capacitive technology for their smartphones and tablets. Advances in material science and manufacturing processes made capacitive touch more affordable and reliable for mass production.

Wides-pread Adoption & Beyond

Capacitive touchscreens became the standard for smartphones, tablets , laptops, and even home appliances like refrigerators and thermostats.

Innovations like force touch and haptic feedback enhanced the tactile experience, simulating physical buttons. Capacitive touchscreens now integrate with AI and IoT devices, enabling smart interactions in diverse settings. Flexible and foldable capacitive displays have emerged, further broadening their application.

How does Capacitive Touch Panel Work?

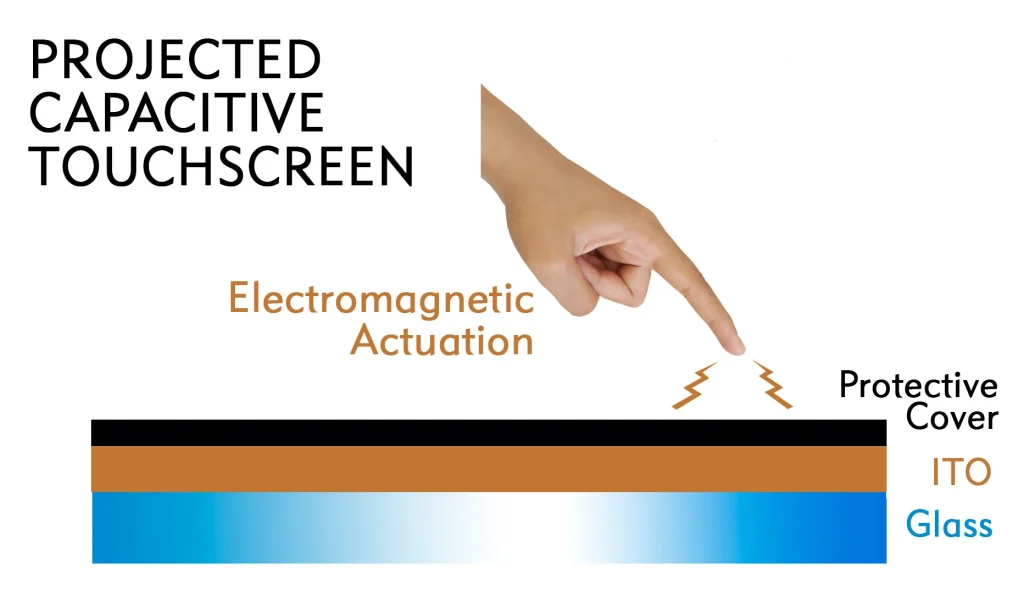

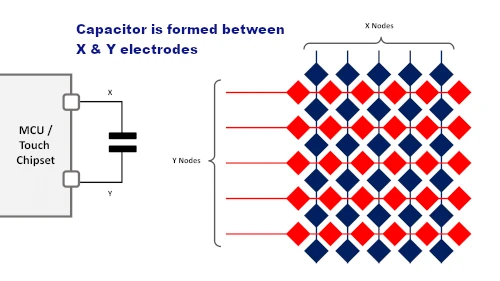

Grid of Electrodes: A projective capacitive touchscreen consists of a grid of transparent electrodes, typically made of indium tin oxide (ITO), that is embedded within the display panel. These electrodes are arranged in a horizontal and vertical pattern.

Capacitance Detection: When a conductive object, such as a human finger, touches the screen, it forms a capacitor with the underlying electrodes. The capacitance of this capacitor changes based on the proximity and pressure of the touch.

Signal Processing: The touchscreen controller measures the changes in capacitance across the grid of electrodes. By analyzing the patterns of capacitance changes, it can accurately determine the location of the touch.

Touch Detection: The controller then processes the detected touch information and sends it to the device’s operating system, which interprets the touch input and performs the appropriate action.

Capacitive Touch Implementations

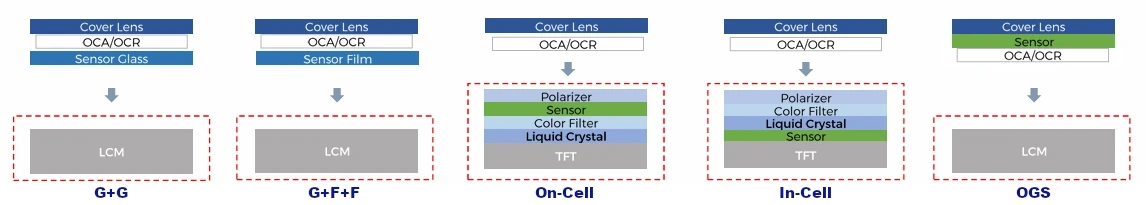

The effectiveness of PCAP depends on how the touch sensors are implemented within the touch display module. The primary methods include GG (Glass-Glass), GFF (Glass-Film-Film), On-Cell, and In-Cell, OGS (One Glass Solution). Each has distinct structural and functional attributes.

GG (Glass-Glass)

Structure:

Two layers of conductive glass: one acts as the sensor, the other as the protective cover.

Pros:

– High durability and scratch resistance.

– Superior optical clarity.

– Precise touch sensitivity.

Cons:

– Higher cost due to glass manufacturing.

– Increased thickness compared to other designs.

Applications: Premium devices like high-end smartphones and automotive displays.

GFF (Glass-Film-Film)

Structure: Two layers of conductive film sandwiched between a protective cover glass and the LCD.

Pros:

– Cost-effective.

– Flexible during manufacturing.

– Suitable for budget devices.

Cons:

– Reduced optical clarity due to multiple layers.

– Less durable compared to glass-based solutions.

Applications: Entry-level devices like budget tablets and touch panels.

On-Cell

Structure: Touch sensors are applied on the top layer of the LCD panel but beneath the protective cover glass.

Pros:

– Balanced thickness and performance.

– Easier to manufacture compared to in-cell.

– Cost-effective compared to in-cell while maintaining good optical performance.

Cons:

– Slightly thicker than in-cell designs.

– Optical interference is possible due to additional sensor layers.

Applications: Mid-range smartphones, automotive displays, and general-purpose touch panels.

In-Cell

Structure: Touch sensors are embedded directly into the LCD panel’s layers, such as the TFT or color filter.

Pros:

– Thinnest profile among all implementations.

– Fewer layers reduce reflection and enhance brightness.

– Simplifies manufacturing by integrating display and touch.

Cons:

– Challenging and costly to manufacture.

– Limited repairability; damage to touch sensors often requires replacing the entire display.

Applications: Flagship smartphones, slim tablets, and premium devices.

OGS (One Glass Solution)

Structure: Touch sensor is integrated into the cover glass, eliminating the need for an additional sensor layer.

Variants:

– Full Lamination OGS: Uses optical bonding for seamless integration.

– External Sensor OGS: Conductive layers are on the outer glass surface.

– Internal Sensor OGS: Conductive layers are embedded within the glass.

Pros:

– Thinner and lighter.

– Excellent optical quality with minimal parallax.

– Durable, depending on sensor placement.

Cons:

– High manufacturing complexity.

– Fragility during production.

Applications: Sleek devices like flagship smartphones and wearables.

Comparison of PCAP Implementations

| Feature | G+G | G+F | On-Cell | In-Cell | OGS |

|---|---|---|---|---|---|

| Thickness | Moderate | Thickest | Thin | Ultra-Thin | Thinnest |

| Durability | High | Moderate | High | Moderate | High |

| Optical Clarity | High | Low | Moderate | Excellent | Excellent |

| Cost | High | Low | Moderate | High | Moderate to High |

| complexity | Moderate | Low | Moderate | Very High | Hign |

| Repairability | High | High | Moderate | Low | Moderate |

Benefits of Capacitive Touch

Better Visuals: Projected capacitive touchscreens have better optical clarity due to the absence of additional layers needed in resistive touch screens, provide a high level of contrast, optical clarity, and the finest visual experience, resulting in sharper images and brighter colors.

High Sensitivity: Capacitive touch screens are highly sensitive, responding to even the slightest touch. This allows for a more intuitive user experience and improved accuracy.

Multi-touch Support: Capacitive touch technology works on the principle of change in capacitance due to human touch. And it can detect multiple simultaneous touches, thus supports advanced gesture recognition, such as swiping, rotating, zooming and pinching. Advanced version of capacitive touch – PCAP touch sensors can handle up to 10 simultaneous touches and allow input from light-gloved hands, offering seamless operations in medical, military and many other devices used in diverse settings.

Durability: Capacitive touch screens are made of solid glass, which is more durable than the flexible plastic used in resistive touch screens.

Accuracy & Stability:

Projected capacitive touch screens offer a high level of accuracy and have a rapid response time. It is, therefore, considered reliable to use in interactive touch devices. PCAP touch sensors include a glass substrate with Indium Tin Oxide (ITO) conductive coating that does not change over time. Therefore, the ITO stays firm in its position, and its electrical properties also remain unchanged. As a result, the accuracy and stability of the sensor does not change over time.

Response time

The sensitivity of a capacitive touch display also contributes to excellent response times. As a user touches the screen at different locations, the surface can register these movements with a high degree of accuracy. A capacitive touch screen also performs very well when the user’s finger or stylus is dragged across the surface. This makes capacitive touch a preferred choice for graphic design and audio-visual applications.

Damage Limitation:

Projected capacitive touch screens have highly durable glass surfaces layered over the grid-patterned substrate. Hence, they cannot be damaged to the point where they will not function unless the substrate grid gets broken. As a result, they are considered extremely robust solutions for applications of heavy use or public areas.

Applications of Capacitive Touch Technology

Smartphones and Tablets: The most common application for projective capacitive touchscreens is in smartphones and tablets, where they enable intuitive interaction with apps and content.

Interactive Displays: These touchscreens are used in interactive displays for retail, education, transportation and entertainment purposes.

Industrial Control Panels: They are found in industrial control panels, such as HMI for machinery operation and monitoring.

Point-of-Sale (POS) Systems: Projective capacitive touchscreens are used in POS systems for customer interactions and transactions.

How to Clean a PCAP Screen

The best way to clean a capacitive touchscreen is to use a soft cloth dipped in rubbing alcohol or a mild nonabrasive soap and water solution. Using a dry cloth may damage the surface. However, a microfiber cloth helps remove fingerprints from the surface.

Follow these steps to clean a capacitive touchscreen:

- Dampen a soft cloth or microfiber cloth with isopropyl alcohol or a mild nonabrasive soap and water solution, and then gently wipe the touchscreen clean.

- Wipe the screen and edges dry.

- Ensure the glass and screen edge are completely dry before using the device.

Conclusion

When it comes to durability and greater touch precision, projected capacitive touch screens are always at the top of the list. The sensor allows touch operations even behind screen protectors, privacy screens, or vandal-proof glass.

In conclusion, Projected Capacitive (PCAP) technology is the foundation of modern touchscreens, offering unmatched performance in sensitivity, durability, and design flexibility. Its various implementations—GFF, GG, OGS, in-cell, and on-cell—cater to different device requirements and price points, ensuring its adaptability across industries. While each implementation has trade-offs, the versatility and user experience offered by PCAP make it the clear choice for today’s touch-enabled devices. Its dominance is expected to continue as innovations further enhance its capabilities, solidifying its position as the preferred touch technology for years to come.

And Menco with over 10 years experience in providing PCAP solution, is your best partner on such project.